Double (or triple) the life of your home’s paint

Proper maintenance can double or even triple the lifespan of your paint job, saving thousands over the life of your home. Yea, no joke. A great paint job doesn’t just make your home look beautiful — it protects it. Your paint serves as the first line of defense against moisture, sunlight, and wear. Seal up cracks, catch flaking and chalking early, and you’ll prevent moisture from getting under the paint and causing the damage that makes the house look like it needs a new paint job.

Here’s the overview that really drives this home:

How Paint Longevity Really Differs

1. Neglected Paint (3–5 years)

Paint begins to fade, crack, or peel within just a few seasons.

Surfaces may absorb moisture, leading to wood rot or siding damage.

Homeowners often end up repainting twice as often — doubling their costs.

2. Moderately Maintained Paint (6–8 years)

Occasional cleaning and minor touch-ups extend the life noticeably.

You may see mild fading or surface wear over time, but the coating remains protective.

This level of care saves money and prevents most early deterioration.

3. Well-Maintained Paint (10–12+ years)

Regular washing, early touch-ups, and caulk maintenance keep the surface sealed and vibrant.

Surfaces stay clean, colors remain rich, and the protective layer continues to perform.

You’ll repaint less frequently, saving thousands while preserving curb appeal and structural integrity.

Why Paint Maintenance Matters

Think of your paint like a roof coating or a car finish: it looks great on day one, but over time, weather, dust, and UV rays start to wear it down.

Neglected paint can fade, crack, and peel within 3–5 years.

Well-maintained paint can last 8–12 years or more before requiring a full repaint.

That difference can mean spending $10,000 once every decade instead of twice — and avoiding costly wood rot, water intrusion, and surface repairs along the way.

Exterior Paint Maintenance Tips

Wash Annually

Use a low-pressure wash or soft brush with mild detergent to remove dirt, pollen, and mildew. Keeping the surface clean prevents grime buildup that traps moisture and breaks down coatings.Inspect Every Spring and Fall

Look for cracking, chalking, or peeling. Pay special attention to south- and west-facing walls that take the most sun, and to trim around windows and doors where water can infiltrate.Touch Up Early

When small chips or hairline cracks appear, spot prime and paint right away. A few minutes now prevents full-scale repainting later.Maintain Caulking and Seals

Reapply flexible exterior caulk where joints or seams open. Failing caulk is one of the biggest causes of premature paint failure.Manage Vegetation

Keep shrubs and trees trimmed away from painted surfaces. Plants trap moisture and can abrade paint on windy days.

A Quick Plug about Right Hand Home

We are all about educating and supporting homeowners- we don’t just paint and leave — we help homeowners understand how to maintain what we build so they get the most out of their investment. We believe craftsmanship isn’t complete until it’s protected.

When we paint, we give clients:

A maintenance guide for your specific materials and climate

Warranty-backed coatings with proven performance

Optional annual maintenance plans to keep your investment in peak condition

Final Word

Paint is a home’s skin — it protects everything underneath. A few hours a year spent maintaining it can save thousands in repairs, extend a home’s lifespan, and keep it looking sharp year after year.

Protect your home. Protect your investment.

Deck Stain- What to Expect and ROI

Building a deck is one of the best ways to add beauty and usable space to your home. But whether your deck lasts 25 years or starts falling apart after 8 years depends less on luck and more on maintenance, materials, and exposure.

If you’ve ever wondered “How often do I really need to stain my deck?” or “What difference does it make if I maintain it or not?”, this guide is for you.

🛡️ The Role of Stain in Deck Longevity

Oil-Based vs. Water-Based Stains

Oil-based stains penetrate deep into the wood fibers, repelling water, blocking UV rays, and resisting mold. They move with the wood as it expands and contracts, making them less likely to peel, and keep the wood fibers from getting dry and brittle.

Water-based stains sit more on the surface, dry faster, and are easier to clean up—but don’t penetrate as deeply.

📊 Impact on Deck Lifespan (Cedar or Juniper):

No stain at all: 8–12 years before major replacement.

Water-based stain: 15–20 years with upkeep.

Oil-based stain: 20–25+ years with consistent maintenance.

🌞 How Often Should You Restain?

The answer depends on your deck’s exposure:

Full sun and rain/snow exposure: Every 12 months.

Partial shade: Every 18–24 months.

Covered deck: Every 2–3 years.

👉 Tip: Don’t wait until the wood is cracked or gray. If water no longer beads on the surface or the color looks washed out, it’s time to re-stain.

💰 What About Costs?

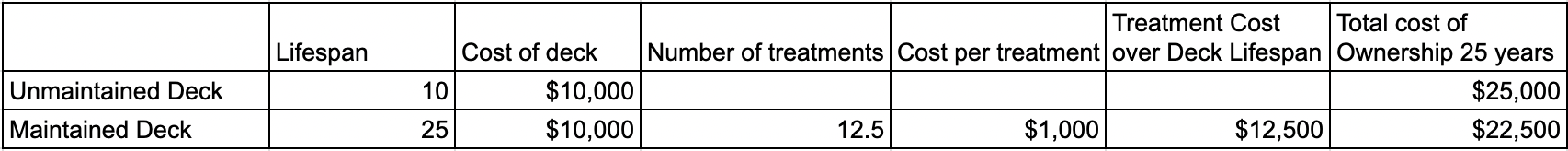

The ROI on regular staining is very clear- it greatly increases useful life while providing an appealing experience for those using it. O

A 12×12 cedar or juniper deck with wood railing in Northwest Arkansas typically costs $6,000–$13,000+ at 2025 prices depending on design complexity and finish details.

✅ Final Takeaways for Homeowners

Stain every 1–3 years depending on exposure.

Choose oil-based stains for maximum protection and longevity.

Clean and inspect yearly—small upkeep prevents expensive rebuilds.

Budget realistically: a quality 12×12 deck in NWA will usually land around $8,000–$10,000 for professional installation.

Your deck can be a short-term feature or a long-term investment. With regular care, it’ll not only last decades but also stay a space you’re proud to show off.

How We Build Decks the Right Way

At Right Hand, building a deck isn’t just about wood and screws—it’s about lasting quality, smart design, and total trust. Here’s how we do it differently:

🔨 Craftsmanship That Holds Up

Most decks start to wobble or rot within a few years. Ours don’t.

Ground-contact-rated lumber: We only use premium pressure-treated lumber where it counts. There is a difference between ground contact and plain pressure treated lumber.

Proper post anchoring: We dig deep and set every post right, so your deck doesn’t shift or sink. Minimum of 24” of depth- it’s a little more sweat and a lot more life.

Screwed, not just nailed: Screws hold longer, resist pull-out, and keep boards flush.

📐 Design That Fits You—and Your Home

No cookie-cutter layouts here.

We tailor every deck to fit your lifestyle, yard, and budget.

We consider traffic flow, shade, furniture placement, and sight lines.

Want a built-in bench? Pergola? Hidden storage? We make it happen.

🧰 Structure You Can Trust

It’s what’s underneath that counts.

Ledger properly flashed to prevent rot where your house meets the deck.

Joists spaced for strength, not shortcuts. Expect 12”-16” spacing. Many will cut materials and labor time by doing 24”.

Railings that don’t wiggle, built to exceed code and feel solid under hand.

🔍 Attention to the Little Things

You might not notice at first glance—but you’ll feel the difference every day.

Board spacing that drains well but feels smooth underfoot.

Clean cuts, tight miters, and a layout that shows real pride.

Fasteners placed cleanly and consistently, not haphazardly blasted in.

🛠️ Here for the long haul.

We stand behind our work.

You get clear communication from start to finish.

We walk you through material choices, layout options, and maintenance tips.

If something’s not right, we make it right—no ghosting, no excuses.

We build the best for your budget

Our entry-level decks are like a Toyota: practical, reliable, and built to last.

Want something custom, exotic, or ultra-modern? We can go all out hidden fasteners, exotic woods, integrated lighting, and more.

Ready for a deck that lasts longer, looks better, and feels right under your feet?

Let’s build something you’ll love.

The Real Cost of a Fence: Why Quality Matters & How to Spot It

Quality fencing- there’s a difference.

Just like vehicles, there are cheap fences, good fences, and luxury fences. At Right Hand, we simply don’t do cheap— our entry-level builds are built to last, fairly priced, and known to hold value for years. We don’t do disposable. We don’t cut corners. And we certainly don’t build anything we wouldn’t want on our own property.

If you’re shopping fencing quotes, here’s how to spot true quality—and how homeowners get burned by going with the lowest bid.

1. Lumber Selection: It All Starts Here

Not all pressure-treated wood is equal. A lot of contractors use above-ground rated pressure-treated lumber for posts and runners. That wood is cheaper—and completely wrong. It will rot from the base up, often in just a few years.

We use ground-contact-rated pressure-treated lumber for anything that touches dirt or concrete. It costs more. It lasts longer. That’s the difference between a fence that leans at year three and one that’s still standing tall at year ten.

2. Reinforced Gates: Because Sagging Isn’t a Vibe

Most gates are built from leftover wood, slapped together and hung with hardware that barely holds. What happens next? Warping. Dragging. Latches that never quite catch.

Our gates are built to last. They're square, rigid, and designed to stay that way. We pair them with heavy-duty, adjustable hinges and easy-to-use latches—so you can open and close your gate with one hand for the next 15 years. We offer a steel frame upgrade that is simply bomb proof!

3. Reinforced Gate Posts: Built Like a Bridge

Every swing of a gate puts stress on the post. And yet, most contractors use the same 4x4 post as the rest of the fence.

We use 4x6 pressure-treated posts at every gate. Why? Because bigger is stronger. That extra width resists twisting, sagging, and the sideways pressure that rips standard posts out of the ground over time.

4. Hole Depth: No Shallow Work Here

The most common failure we see? Posts popping, tilting, or heaving after a winter or a hard rain. Why? Shallow holes and not enough concrete.

We dig deep—24" to 30" minimum—every time. Posts are set with fast-setting concrete, checked for plumb in all directions, and braced as they cure. No guesswork. No wobbles.

5. Plumb and Level: It Makes or Breaks the Look

Nothing screams “cheap job” louder than a crooked fence line. It might be “close enough” to some guys, but we know better.

We build laser-straight lines with plumb posts, level rails, and consistent spacing. It doesn’t just look better—it performs better. Every gate latches clean. Every board lines up. And your fence becomes something you’re proud to look at every day.

6. Nail Placement, Nail Count, and Fasteners

Many crews try to save time and money by slapping on fewer nails or using cheap fasteners. That shortcut shows up fast—in curled pickets, popping boards, and entire panels separating in storms.

We use ring-shank galvanized nails or stainless screws, placed correctly. That means two fasteners per picket, all driven into the purlins with care and consistency. It’s the kind of detail that lasts.

7. Purlin Count and Spacing: The Hidden Strength

A lot of fences only use two horizontal rails (purlins). That may work for short fences—but for 6' privacy builds, it's a weak spot.

We often use three purlins per panel to prevent warping and ensure better picket support over time. More structure equals less sag and better overall strength.

8. Hardware You Can Feel

Flimsy latches and misaligned hinges are the hallmark of low-cost jobs. They fail quickly, rust out, or simply stop functioning.

We install high-quality, corrosion-resistant gate hardware—the kind you find on commercial builds. Gates swing smoothly and close securely, every time.

A Final Word: Don’t Buy a Fence Like You’re Buying Fast Food

Yes, you’ll find someone who will build it cheaper. But ask yourself:

Will it still be standing straight in five years?

Will the gate still latch?

Will you be proud of it—or just tolerate it?

We build fences the way fences should be built. Whether you’re going for affordable and functional or full-on showpiece, our work is made to last, look great, and hold its value.

Want a high value fence? We’ve got you. Want the best of the best? We do that, too.

Just don’t get tricked into a lemon.